Stamped Sheet Metal - Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. The sheet metal stamping process is a strategic advantage that can set your business apart. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Blanking involves cutting the metal. Precision, efficiency, and innovation are at its. The metal is fed into a press, where.

The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The metal is fed into a press, where. In this process, a flat sheet of metal,. Blanking involves cutting the metal. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging.

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Blanking involves cutting the metal. The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. In this process, a flat sheet of metal,. The metal is fed into a press, where.

Sheet Metal Stamping Process Aranda Tooling

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. In this process, a flat sheet of metal,. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a.

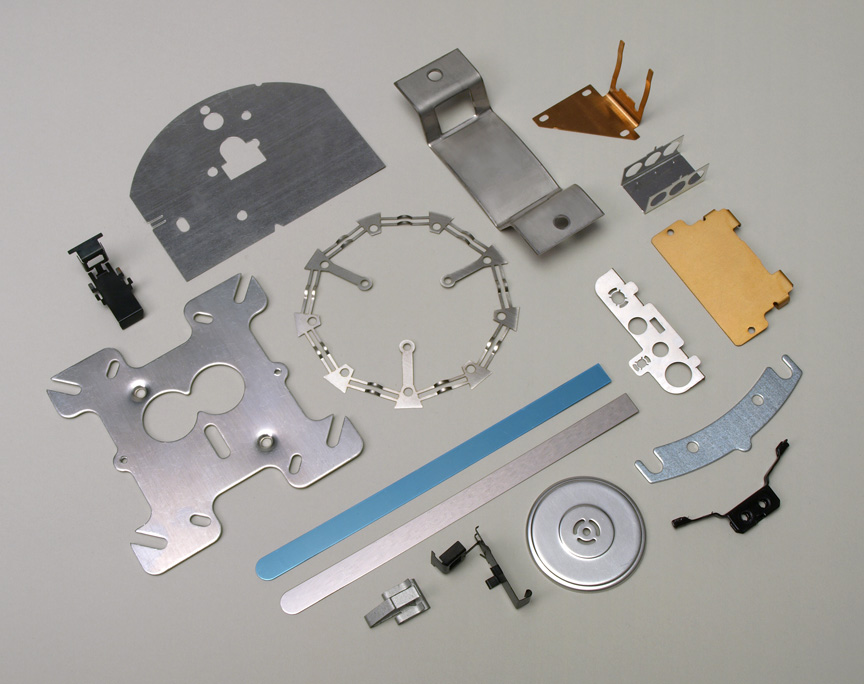

Custom Sheet Metal Stamping Services and Parts Dunkirk Metal Products

The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. In this process, a flat sheet of metal,. Blanking involves cutting the metal. The metal is fed.

Custom Stamped Sheet Metal Parts that are Made In USA

Precision, efficiency, and innovation are at its. The metal is fed into a press, where. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. In.

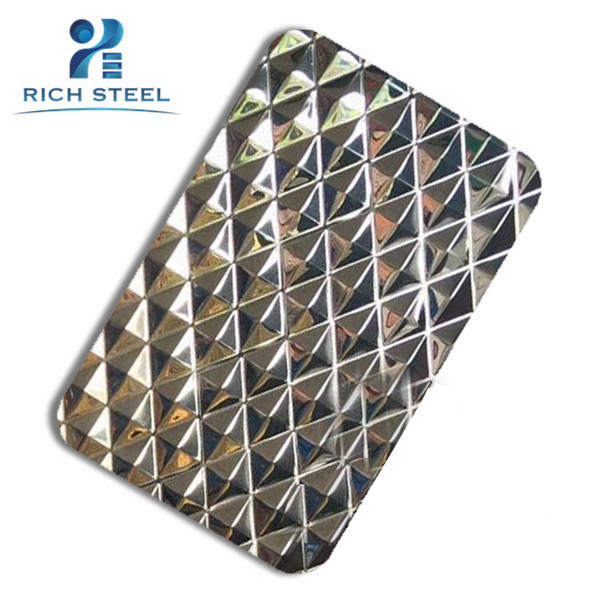

Salt Spray Resistance Stamped Metal Panels , Exquisite Decorative Sheet

Precision, efficiency, and innovation are at its. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Blanking involves cutting the metal. Stamping (also known as pressing) is the process of placing flat sheet metal in.

304 4X8 Decorative Color Embossed Stamped Metal Sheets RichSteel

Precision, efficiency, and innovation are at its. In this process, a flat sheet of metal,. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. The metal is fed into a press, where.

Stamped Stainless Steel Sheet antiskid stainless steel ARTIST

The sheet metal stamping process is a strategic advantage that can set your business apart. Precision, efficiency, and innovation are at its. Blanking involves cutting the metal. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. In this process, a flat sheet of metal,.

Stamped Stainless Steel Sheet antiskid stainless steel ARTIST

The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a.

Stamped Stainless Steel Sheet antiskid stainless steel ARTIST

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The sheet metal stamping process is a strategic advantage that can set your business apart. The steps of the sheet metal stamping process include blanking, piercing,.

Sheet Metal Stamping Process Step by Step YouTube

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. The sheet metal stamping process is a strategic advantage that can set your business apart. In this process, a flat sheet of metal,. Stamping or pressing is a manufacturing process used to.

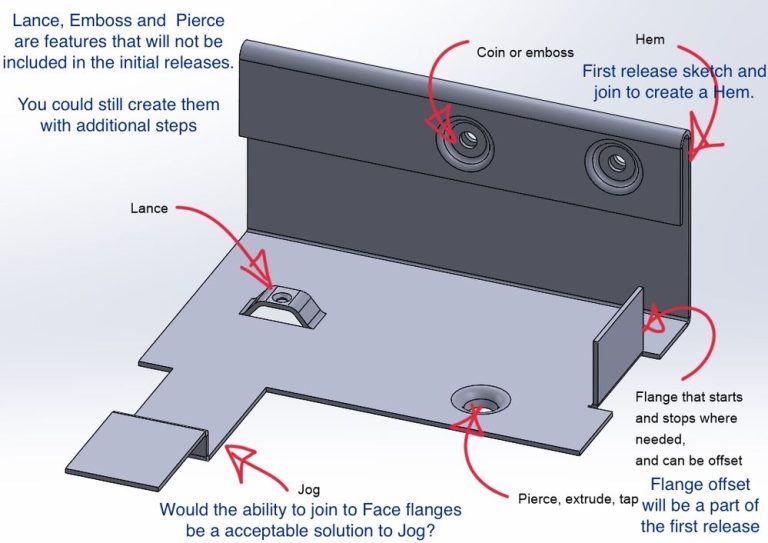

UNDERSTANDING SHEET METAL STAMPING GUIDELINE FOR BUYERS AM

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The metal is fed into a press, where. Blanking involves cutting the metal. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The sheet metal stamping process is a strategic advantage that can set your.

The Metal Is Fed Into A Press, Where.

The sheet metal stamping process is a strategic advantage that can set your business apart. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,.

Blanking Involves Cutting The Metal.

Precision, efficiency, and innovation are at its. The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging.